Photo Offset

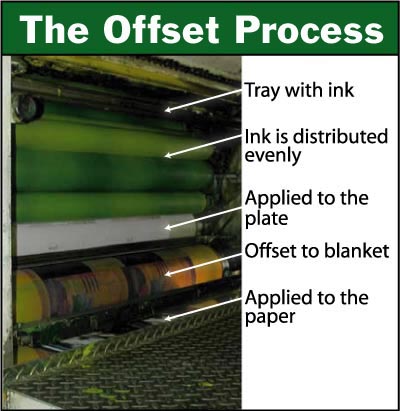

The offset lithography process works by first transferring an image photographically to thin metal, paper, or plastic printing plates. Unlike other forms of printing, in offset lithography the image on the printing plate is not recessed or raised. Rollers apply oil-based ink and water to the plates. Since oil and water don't mix, the oil-based ink won't adhere to the non-image areas. Only the inked image portion is then transferred to a rubber blanket (cylinder) that then transfers the image onto the paper as it passes between it and another cylinder beneath the paper. The term offset refers to the fact that the image isn't printed directly to the paper from the plates, but is offset or transferred to another surface that then makes contact with the paper.

(From: http://desktoppub.about.com/cs/printing/g/offsetlitho.htm)

Unlike relief and intaglio printing where the image to be printed is raised above or sunk below the surface of the printing plate, in lithography the printing surface is flat with both image and non-image areas at the same level on the printing plate. Invented in 1798 by Alois Senefelder, lithography uses the fact that oil and water don't mix as the basis of the printing process. A flat stone such as limestone or a metal plate is treated so that the image area attracts oil-based inks and the wet non-image areas repel the oil-based inks.

(From: http://desktoppub.about.com/cs/printing/g/lithography.htm)

Offset Lithography

Offset Lithography is by far the most common form of commercial printing.

The basic principle on which it works is that oil and water do not mix. A litho printing plate has non-image areas which absorb water. During printing the plate is kept wet so that the ink, which is inherently greasy, is rejected by the wet areas and adheres to the image areas.

Artwork is produced digitally with graphic design software. An imagesetter is then used to produce films (either positive or negative). When printing with more than one colour there is a separated film for each ink used. Each film is used to make a printing plate by a photochemical process. The plate surface has non-image areas which absorb moisture and repel ink.

The flexible plates, which can be made of a variety of materials, are attached to the plate cylinder. The plate is kept moist throughout so that ink only adheres to image areas.

During every cycle of the press the ink image is first transferred to a rubber surfaced blanket cylinder and from there to the paper. This indirect method is the 'offset' after which the process is named. The blanket cylinder's flexibility both preserves the delicate plate and conforms to the surface of textured papers.

After printing the sheets are taken for finishing - trimming, folding and binding.

The press can either be fed with paper one sheet at a time (Sheet fed) or from a large roll of paper (Web). Web printing is normally reserved for large scale, long run work such as magazines and catalogues.

The basic stages of the modern production process are:

1 Original artwork - photographs, illustrations and text - are scanned and entered into a computer.

2 These elements are combined into a document using page makeup software.

3 Full size films are output using a high-resolution imagesetter. These could be either positives or negatives.

4 Printing plates are made from the films using a photochemical process. The plates are exposed to high-intensity light through the films and then chemically treated so that non-image areas are water absorbent.

5 The flexible plates are attached to the plate cylinders of a litho press and the job is printed.

This diagram shows the production process for a colour job. See Four Colour Process Printing for a detailed explanation.

(From: http://www.bobs.co.uk/print/Offset.html)

![]() Electronic

Publishing Home Page

Electronic

Publishing Home Page

Department of Communication, Seton Hall University