Customized Printing

Digital printing presses that use electronically imaged drums can provide a wide range of new printing possibilities with a feature called customization. As a document is printed, certain images or text on a page can vary, while other elements on the page remain the same. This is a singular advantage of true digital systems as compared to digitally plated offset presses.

How Does Customization Work? Images or text that will vary are identified in the document using the page layout program in conjunction with software controls on the press. Variable elements are contained in a database, which is stored in memory. As the document prints, the press substitutes elements as it electronically re-images variable areas of the drum. The number and size of substituted images or text are constrained by memory and press limitations, and substituting large four-color images will increase RIP time. Check beforehand to find out the type of customization that's possible.

Customizing Documents

Simple black text customization has been common on form letters and other text-based advertising, but digital presses offer greater possibilities with images and four colors. Customizing documents will often increase impact and response rates. Individual real-estate flyers can be printed with a photograph of each agent, while boilerplate information remains the same. Catalogs can be tailored to individual tastes and interests, and thus printed with fewer (but more relevant) pages.

The technology of customization continues to evolve, as vendors develop new software, file formats, and press enhancements to increase the ease and speed of printing variable data.

By offering quick turnaround and affordable overall costs for four-color short runs, digital presses are ideal for many different kinds of documents, brochures, artwork comps, manuals, and other printed material. The ability to customize individual pages with images and text in a single run also opens up numerous possibilities for direct mail campaigns, personal marketing approaches, and targeted documents.

The examples shown here are designs from around the world that were printed on Agfa's digital printing press, the Chromapress.

(From “An Introduction to Digital Color Printing” by Agfa Educational Publishing. Out of print)

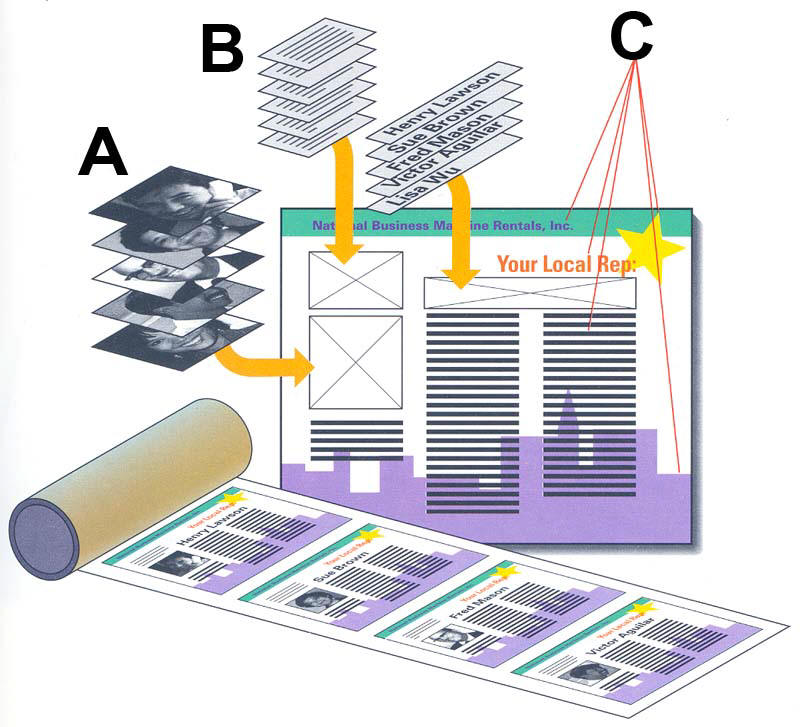

An Example of Customized Digital

Printing![]()

A brochure

that contains some standard company information can be

targeted to specific regions by

using

variable data to

substitute in names, descriptions, and photographs of different

regional representatives. Some systems even allow

varying

frequency of data changes.

information can be

targeted to specific regions by

using

variable data to

substitute in names, descriptions, and photographs of different

regional representatives. Some systems even allow

varying

frequency of data changes.

A-Variable

Images

A-Variable

Images

Images, usually in EPS or TIFF format, are stored in a database and substituted into the variable area. Images substituted into the same area must all be the same size. Most systems allow numerous elements to be varied, up to a specified total area of a page. In general, four-color images will be slower than those with fewer colors.

B-Variable Text

Text is also stored in a data base, then flowed into the variable areas. Though line breaks may vary, all text substituted into the same variable area should be approximately the same length. Make sure to check with your print shop to understand the details of text substitution. Customization software may not provide the same typographic control that exists in the page layout program.

C-Unchanging Elements. Most of the page and the remainder of the document consists of text and images that do not change. The greater the percentage of fixed elements, the faster the job will be RIPed.

The variable areas on the drum are electronically re-imaged by the light source with the substituted image or text. Some systems must pre-RIP all variable data, which significantly slows processing time. Others pre-RIP only fixed elements and can RIP variable data on the fly.

(From “An Introduction to Digital Color Printing” by Agfa Educational Publishing. Out of print)

![]() Electronic

Publishing

Home Page

Electronic

Publishing

Home Page

Department of Communication, Seton Hall University