One source lists the following printing processes:

Letterpress (Relief) printing: the original ,mechanical Gutenberg printing process. Limited use today. (See “Letterpress”, below)

Flexography: a relief process used for special purposes such as packaging. (See “Flexography”, below)

Gravure (Intaglio) a more expensive process which produces higher quality color than Letterpress. Only specialized use today. (See “Gravure”, below)

Photo Offset Lithography: A chemical method of ink transferal and the primary major printing process today. (See separate “Photo Offset” page.)

Screen Printing: A very flexible process used extensively in specialty printing and advertising. (See “Screen Printing", below)

Xerography: An electrostatic method of image transfer onto smooth paper. (See “Xerography” below.)

Ink Jet Printing: Printing by small jets propelling droplets of ink onto paper. (See "Ink Jet Printing", below

Engraving - think fine stationery

Thermography - raised printing, used in stationery. (see "Thermography" below.)

Reprographics - copying and duplicating

Digital printing: including direct to press and printing on demand. Possibly the printing processes of the future. (See separate “Digital Printing” page.)

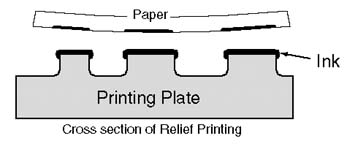

Letterpress Printing The oldest method of printing used by Gutenberg. The image area is raised, usually in metal, and the non-image area is recessed.

The

raised surface can be obtained by cutting away the white areas with hand

tools (as in block printing or

wood-engraving), by acid etching

of metal (as in photoengraving), by light-hardening a photo-emulsion

(photo-polymer plates), or by casting from a carved or punched matrix

(as in metal

type). There are other methods for

creating the a raised surface, but most letterpress techniques tend to

fall under the above categories.

Once a relief surface has been prepared it is put in the press. A roller

(or sometimes a dauber) is used to place ink on the type or block, which

is then pressed against paper. Multiple blocks are used to create images

with more than one color.

From: http://work.colum.edu/~matma/letterpress/letterpress.html

The use of letterpresses is on the decline being replaced with faster and more efficient printing presses such as the offset lithographic press or the flexographic press. The amount of setup required to prepare the equipment to print a job is significant. For example, the image must be metal cast prior to print versus offset printing plates which are comparatively cheaper and require less time to make.

(From: http://www.pneac.org/printprocesses/letterpress/#Overview) (Back to Top)

Flexography: Frequently used for printing on plastic, foil, acetate film, brown paper, and other materials used in packaging, flexography uses flexible printing plates made of rubber or plastic. The inked plates with a slightly raised image are rotated on a cylinder which transfers the image to the substrate. Flexography uses fast-drying inks, is a high-speed print process, can print on many types of absorbent and non-absorbent materials, and can print continuous patterns (such as for giftwrap and wallpaper).

(From: http://desktoppub.about.com/cs/printing/g/flexography.htm) (Back to Top)

Gravure: With gravure printing an image is etched on the surface of a metal plate, the etched area is filled with ink, then the plate is rotated on a cylinder that transfers the image to the paper or other material. (From: http://desktoppub.about.com/cs/printing/g/gravure.htm)

In the various intaglio printing methods, the area of the image to be printed is recessed into the surface of the printing plate and the recessed areas are filled with ink. The incised image may be etched, engraved with chemicals or tools. The image to be printed is incised into the plates, the incisions filled with ink, and excess ink wiped from the plates. Heavy pressure is applied to transfer the ink from the plates to the paper, leaving the surface slightly raised and the back side slightly indented. (From:http://desktoppub.about.com/cs/printing/g/intaglio.htm)

Gravure printing is characteristically used for long run, high quality printing producing a sharp, fine image. The number of gravure printing plants in the U.S. is significantly lower than other printing processes. This is due, in part, to the cost of presses and components. While a lithographic press will cost in the range of $100,000 the cost of gravure press will be in the range of $1 million. Additionally a single gravure cylinder will cost around $5000 versus around $15 for a lithographic plate. Additionally, the gravure cylinder has a long service life and will yield a very large number of impressions without degradation. (Back to Top)

Thermography: Commonly known as poor man's engraving, thermography produces raised printing similiar in appearance to engraving but using a different process. In thermography, a special powder is added to the ink printed on the paper. The printed piece is heated and the powder and ink mixture dries to form a raised effect on the paper.

(From: http://desktoppub.about.com/cs/printing/g/thermography.htm) (Back to Top)

Screen Printing (Silk Screening)

Screen printing is arguably the most versatile of all printing processes. It can be used to print on a wide variety of substrates, including paper, paperboard, plastics, glass, metals, fabrics, and many other materials. including paper, plastics, glass, metals, nylon and cotton. Some common products from the screen printing industry include posters, labels, decals, signage, and all types of textiles and electronic circuit boards. The advantage of screenprinting over other print processes is that the press can print on substrates of any shape, thickness and size.

A significant characteristic of screen printing is that a greater thickness of the ink can be applied to the substrate than is possible with other printing techniques. This allows for some very interesting effects that are not possible using other printing methods. Because of the simplicity of the application process, a wider range of inks and dyes are available for use in screen printing than for use in any other printing process.

Utilization of screenprinting presses has begun to increase because production rates have improved. This has been a result of the development of the automated and rotary screenprinting press, improved dryers, and U.V. curable ink. The major chemicals used include screen emulsions, inks, and solvents, surfactants, caustics and oxidizers used in screen reclamation. The inks used vary dramatically in their formulations (GATF 1992b).

Screen Printing Process Overview

Screen printing consists of three elements: the screen which is the image carrier; the squeegee; and ink. The screen printing process uses a porous mesh stretched tightly over a frame made of wood or metal. Proper tension is essential to accurate color registration. The mesh is made of porous fabric or stainless steel mesh. A stencil is produced on the screen either manually or photochemically. The stencil defines the image to be printed in other printing technologies this would be referred to as the image plate.

Screen printing ink is applied to the substrate by placing the screen over the material. Ink with a paint-like consistency is placed onto the top of the screen. Ink is then forced through the fine mesh openings using a squeegee that is drawn across the scree, applying pressure thereby forcing the ink through the open areas of the screen. Ink will pass through only in areas where no stencil is applied, thus forming an image on the printing substrate. The diameter of the threads and the thread count of the mesh will determine how much ink is deposited onto the substrates. (From: http://www.pneac.org/printprocesses/screen/) (Back to Top)

Xerography: Dry, electrostatic method of producing images, without the use of negatives or sensitized paper, invented in the USA by Chester Carlson in 1938 and applied in the Xerox photocopier. Also called electrophotography, method of dry photocopying in which the image is transferred by using the attractive forces of electric charges. A beam of light, usually from a laser, is made to strike the original material, e.g., a white page with black lettering. Light rays are reflected off the white areas onto a photosensitive plate over which electric charges have been spread. Charges are neutralized from the areas struck by the rays. Since no light rays are reflected from the lettering, charges are retained on the plate in areas corresponding to the lettered areas of the original. A plastic powder called toner is introduced that sticks to the charged areas. A sheet of paper is then passed between the plate and another charged object that draws the powder from the plate to the paper, forming an image of the original; the powder is fused to the paper with heat. The process has image resolution that is sufficient for printed or written materials, and certain pictorial materials are fairly well reproduced. As the image on the drum is a projected one rather than one made by contact printing, it is possible to produce a copy that is smaller or larger than the original. Variations of the xerographic process are used in such devices as computer laser printers and plain-paper facsimile machines.

(Mostly from: http://www.encyclopedia.com/html/x1/xerograp.asp)

laser printer a computer printer that produces high-resolution output by means of a process that is similar to photocopying . In place of reflected light from an image (as is used in xerography ), a laser printer uses data sent from a computer to turn a laser beam on and off rapidly as it scans a charged drum. The drum then attracts toner powder to the areas not exposed to the light. Finally, the toner is fused to paper over a belt by heated rollers. In a write-black printer the laser positively charges the printed areas to attract the toner, which gives better detail than a write-white printer. In a write-white printer, the beam negatively charges the areas not to be printed to repel the toner, which gives a denser image. Faster, quieter, and capable of producing more attractive results than standard printers, laser printers have become an important means of printing business documents since they became more generally available (1984) for personal computers .

(From: http://www.encyclopedia.com/html/l1/laser-pr.asp) (Back to Top)

Ink jet printing: A printer that propels droplets of ink directly onto the medium. Today, almost all ink jet printers produce color. Low-end ink jets use three ink colors (cyan, magenta and yellow), but produce a composite black that is often muddy. Four-color ink jets (CMYK) use black ink for pure black printing. Ink jet printers run the gamut from less than a hundred to a couple hundred dollars for home use to hundreds of thousands of dollars for commercial poster printers.

The cost of ink cartridges for low-priced printers can make the less-expensive ink jet model more costly in the long run. For example, if the black ink does not come in a separate cartridge, you have to replace the entire four-color unit when you run out of black. Also, for resolution quality, examine text samples, not graphics. Graphics always look better than text. For color quality, be sure that samples from different models are printed on the same kind of paper. Coated specialty papers, although costly, greatly improve the printed results, because they do not absorb the ink like regular copy paper. Ink and paper costs are ongoing, which must be taken into consideration.

Large wide-format ink jet printers are used to produce final output for commercial posters and banners. Such printers can print on vinyl and textiles as well as paper, and their quality is extraordinary. Wide-format printers have also replaced pen plotters that used to "draw" engineering and architectural renderings.

(From The Computer Desktop Encyclopedia) (Back to Top)

![]() Electronic

Publishing Home Page

Electronic

Publishing Home Page

Department of Communication, Seton Hall University